In the relentless environments of heavy industry, where machinery operates under extreme stress, and uninterrupted performance is non-negotiable, Heavy Duty Connectors (HDCs) stand as the undisputed champions of reliable connectivity. Far transcending the capabilities of standard rectangular connectors, these formidable interfaces are purpose-built to withstand the harshest conditions imaginable – from dust and moisture to severe vibration, shock, and temperature extremes. They are the robust, high-performance links that ensure the continuous flow of high current, high voltage, and critical signals, forming the unyielding backbone of modern industrial automation, robotics, energy infrastructure, and transportation systems.

What elevates Heavy Duty Connectors to an indispensable status in demanding applications? It's their ingenious modular design, unparalleled durability, and unwavering commitment to safety and efficiency:

- Engineered for Extreme Durability & Environmental Resilience: The defining characteristic of HDCs is their rugged construction. Featuring robust metal housings (often aluminum or die-cast alloys) and advanced sealing mechanisms, they boast superior IP ratings (e.g., IP65, IP67, IP68), providing exceptional protection against water ingress, dust, dirt, and corrosive substances. This makes them ideal for outdoor installations, dusty factories, and wash-down areas, ensuring long-term operational integrity.

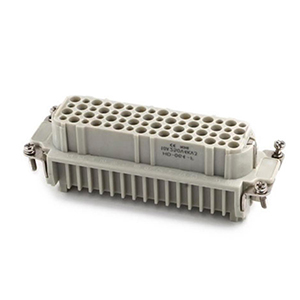

- Unmatched Power & Signal Handling Capacity: Designed to carry substantial electrical loads, Heavy Duty Connectors excel in applications requiring high current and high voltage transmission. Beyond raw power, their modular nature allows for the integration of various inserts and contacts within a single frame, accommodating a wide range of position options for both power and sensitive signal lines. This enables a single connector to manage complex wiring schemes, simplifying installations and reducing cabling clutter.

- Ultimate Modularity & Design Flexibility: The true power of HDCs lies in their highly modular system. Comprising separate housings, frames, and interchangeable inserts (which hold the contacts), these connectors offer unparalleled flexibility. Engineers can custom-tailor solutions by selecting specific contact types (crimp, screw, push-in), varying pin counts, and integrating mixed-contact configurations (combining power, signal, data, and even pneumatic connections) within a standardized rectangular form factor. This adaptability streamlines design, assembly, and maintenance.

- Secure Connection & Enhanced Safety: Safety is paramount in heavy industrial settings. HDCs feature robust locking mechanisms (e.g., double locking levers) that ensure a secure, vibration-proof connection, preventing accidental disengagement. Their large size and clear visual cues further contribute to safe handling and operation, crucial when dealing with high power loads.

- The Backbone of Industrial Connectivity: Our Heavy Duty Connectors are the go-to solution across a spectrum of critical industries: from industrial machinery, robotics, and material handling systems to rail transportation, wind energy turbines, construction equipment, and process control facilities. They provide the reliable, maintainable, and scalable interconnect solutions essential for the continuous operation and evolution of these complex systems.

As industries continue to automate, electrify, and push the boundaries of performance in challenging environments, Heavy Duty Connectors remain at the forefront, providing the unwavering reliability and flexibility demanded by the future of industrial connectivity.

0

0